How to Stop Thermal Bridging with TStuds!

Wood is a conductor or a thermal bridge. It allows heat to flow easily from the exterior to the interior or vice versa. To solve this problem, a company in the States, called US Engineered Wood, has invented the TStud, a framing member that improves the energy efficiency of buildings by acting like a thermal break instead of a thermal bridge.

Link to my Patreon page: / belinda_carr

CHAPTERS

0:00 Introduction

0:47 Dimensions

2:23 Performance

4:55 Ease of use

5:14 Sponsorship

5:52 Price

6:48 Conclusion

MEMBERS

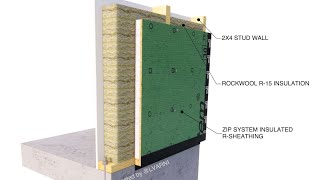

Thermal bridging is the flow of heat by conduction through the studs in a building. Bare Naked T Studs stop the flow of heat because of a gap between the flange and spline. The gap in between is approximately 1.5”. Wooden dowels are installed through one member into the other at opposing angles, forming a weblike pattern.

T Studs can replace most framing members like wall studs, top plates, bottom plates as well as king, jack, and cripple studs. They can be used in either direction. If you need more surface area on the outside to secure sheathing and outside insulation, this surface can face the exterior. If you need more surface area on the inside to secure cabinets and shelves, you can reverse the T stud.

R VALUE

About 25% of a typical wall consists of wood studs which lower the R value of the entire wall. If you use R20 insulation in between the studs, thermal bridging can bring the effective Rvalue down as low as R15. If you put an R20 batt into a steel stud wall, you may only get an effective Rvalue of approximately R5. Steel conducts heat much better than wood, hence why shipping containers are terrible insulators. If you use closed cell spray foam in the T stud and R20 insulation in the rest of the wall, the assembly actually acts like an R20 wall, not R10 or R15. T studs allow a 96% complete thermal break through the wall assembly.

MOISTURE

Another issue with traditional wood studs is moisture accumulation or ghosting. Moist, cool air attracts dust and forms dark lines on the ceiling and in closets where a lot of framing gets mashed together. Accumulation of moisture in the wall can lead to the growth of mold and rot which affects indoor air quality and compromises structural integrity. TStuds act as a thermal break and reduce moisture accumulation in walls.

STRENGTH

T studs are 4 times stronger than traditional studs which fail in the x axis if there's too much of a load on it. T studs don’t behave the same way because they are turned 90 degrees. They don’t deflect or fail in the x axis. While a 2 by 4 can hold 900 pounds and a 2 by 6 stud can hold 2,200 pounds, T studs can hold 8,600 pounds.

INSTALLATION

Installing T studs is very similar to nailing traditional studs so there is a minimal learning curve associated with it. One thing that’s different is the fastening of T studs to the ground. Instead of just a threaded J bolt or lag bolt, you need a wide plate that straddles the two wood studs and transfers its hold down power.

COST

T studs are obviously more expensive than traditional studs but their increased cost is offset in a couple of ways. The first is waste. About 5% of traditional studs are usually too warped and damaged to be used. On the other hand, less than 1% of T studs are unusable. The second is reducing the number of studs needed. These can be spaced 24” on center instead of 16” on center. The third is the reduced weight. T studs are lighter than traditional studs, which lowers the cost of other framing members and even the foundation. The last point is the lower energy consumption of your HVAC system and other appliances. By eliminating the thermal bridge in your walls, the interior space is essentially unaffected by the temperature outside. T studs can help lower your energy consumption and carbon footprint.

The one downside I can think of is that it takes up more interior space because it’s as deep as a 2 by 6. It may not be a viable alternative in tight enclosures when every square foot counts. It’s also not going to be used for interior studs because it’s more expensive and because thermal bridging is not an issue inside. T studs can raise awareness of the problem of thermal bridging and the need to address it.

SOURCES:

• Insulated Studs? This is a BIG Innova...

Fluffy by Smith The Mister https://smiththemister.bandcamp.com

Smith The Mister https://bit.ly/SmithTheMisterYT

Free Download / Stream: https://bit.ly/stmfluffy

Music promoted by Audio Library • Fluffy – Smith The Mister (No Copyrig...

Disclaimer: This video was created for educational/informational purposes and qualifies as Fair Use. If you are the creator or own the footage featured in this video and have reservations please notify me via Youtube comments or email and I will accommodate you

#stud #construction #innovation #architecture #buildingscience