Guided Auger Boring (Thrust Boring) - Allen Watson Ltd - www.allenwatson.com

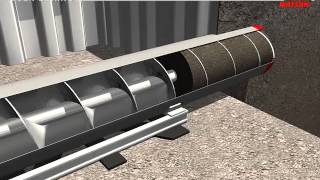

Often referred to as Guided Thrust Boring or Micro Tunnelling.

Compact boring equipment operates from shafts or pits as small as 2.40mØ. Allen Watson designs, owns and operates the widest, most powerful and versatile range of guided auger boring systems for trenchless applications. With jacking forces from 85te to 155te, we provide total trenchless solutions for the installation of gravity pipes, cable ducts or simply where accuracy is paramount.

We are extensively using this as a safe and costeffective alternative to microtunnelling, timber headings and in many instances open cut.

Advantages

Accurate installations +/ 25mm over distances up to 100 metres between pits

Can operate from shafts as small as 2.40mØ

Ideal for gravity drainage pipes, cable ducts or accurate installations

Can install variety of pipe materials, such as clay, steel, PE, concrete or GRP

Dry method of installation unlike micro tunnelling does not generate slurry

Auger boring is unaffected by surface obstacles

No disruption to surface, buildings, road, river, rail or traffic

By boring underground the working area is confined to entry and exit points

Unlike micro tunnelling, Guided Auger can be retracted back to the working pit

Can be used to install pipes in changeable ground conditions

Auger boring is quick and in many cases has lower overall costs

Typical Applications

Steel pipes and ducts from 100mmØ up to 1016mmØ or drainage pipes from DN150 up to DN900.

Distances from 5 metres up to 100 metres have been successfully installed under railways, roads, rivers, airports, buildings, contaminated landfill sites and Sites of Special Scientific Interest (SSSI).

Crossings can be for water, oil, gas, electricity, sewerage, chemicals, communication ducts and outfalls.

![[Internal Document] How to Launching TBM (Tunnel Boring Machine)/First technology in Vietnam](https://i.ytimg.com/vi/qoxgyUFEiXE/mqdefault.jpg)