AC Pressures Subcooling and Superheat

Bryan with HVAC School goes over AC pressures, subcooling, and superheat in his troubleshooting mindset presentation from the BTrained HVAC training event in Birmingham, AL. Bryan also talks a bit about his educational photosharing app, MechPic.

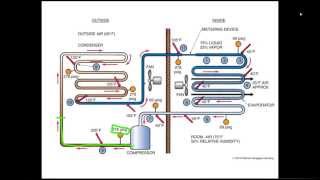

The suction pressure and suction saturation give us an idea of the refrigerant’s boiling temperature. Evaporation happens at the surface and not necessarily at the boiling temperature; on the other hand, boiling happens throughout the entire substance and occurs at the boiling temperature. So, the “evaporator” is really a heat absorber where boiling occurs.

A rule of thumb for suction saturation is that it should be around 35 degrees below the indoor ambient temperature at 400 CFM per ton. That differential or temperature split, also known as the design temperature difference (DTD), is typically 3035 degrees in highhumidity markets that use 350 CFM per ton like Florida and Alabama, where the conference took place. Lower suction pressures generally result in a higher DTD, and higher suction pressures usually result in a lower DTD.

When we look at head pressure, we’re actually learning about the condensing temperature over ambient (CTOA). The CTOA is the temperature split between the outdoor ambient temperature and the condensing temperature. In general, CTOA tends to fluctuate a bit more than evaporator DTD, but a rule of thumb is that it should be about 1520 degrees above the outdoor ambient temperature. SEER ratings may also affect CTOA.

A ratio of head pressure to suction pressure is your compression ratio. Higher compression ratios tend to lead to reduced compressor performance (moving fewer BTUs).

Even though we tend to see high head pressure as the main problem to avoid, we should be aware that low head pressure is possible. There needs to be an energy or pressure differential for matter to move from one place to another, and we’ll have trouble moving refrigerant if the head pressure is too low. The most important thing is to make sure that the system is working in accordance with its design.

Superheat is the degrees a vapor is above its saturation temperature, and it really tells us the amount of liquid that’s stacked in the evaporator. However, the evaporator and compressor superheat could be quite different due to heat gains in the suction line. Generally, we want to see 10 degrees of evaporator superheat (+/5 degrees) on many AC systems. The TXV is supposed to keep superheat constant; however, some possible system problems can affect superheat beyond the TXV’s control (such as significant liquid line restrictions, though there are exceptions to that example).

On the other side, subcooling refers to the temperature of a liquid below its saturation temperature. In an HVAC system, subcooling indicates how much refrigerant we’ve “stacked” in the condenser; lower subcooling indicates that we have little liquid refrigerant stacked in the condenser, and higher subcooling indicates that we have a lot of liquid refrigerant stacked in the condenser. (There can, but not always, be temperature drops across liquid line restrictions.) Refrigeration systems with receivers don’t necessarily have to rely on subcooling values to indicate refrigerant storage (a rule of thumb for residential A/C systems is typically 10 degrees +/3). When we measure subcooling, we really want to know if we’re feeding the metering device a full column of liquid. If we want to increase subcooling, we can do that by reducing the liquid temperature via mechanical subcooling or increasing the condensing temperature. (However, we don’t want too much subcooling.)

When we use the manufacturer’s specs to set our superheat and subcooling, we might actually be reducing the equipment performance, so we have to know exactly what our goals are.

Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/.